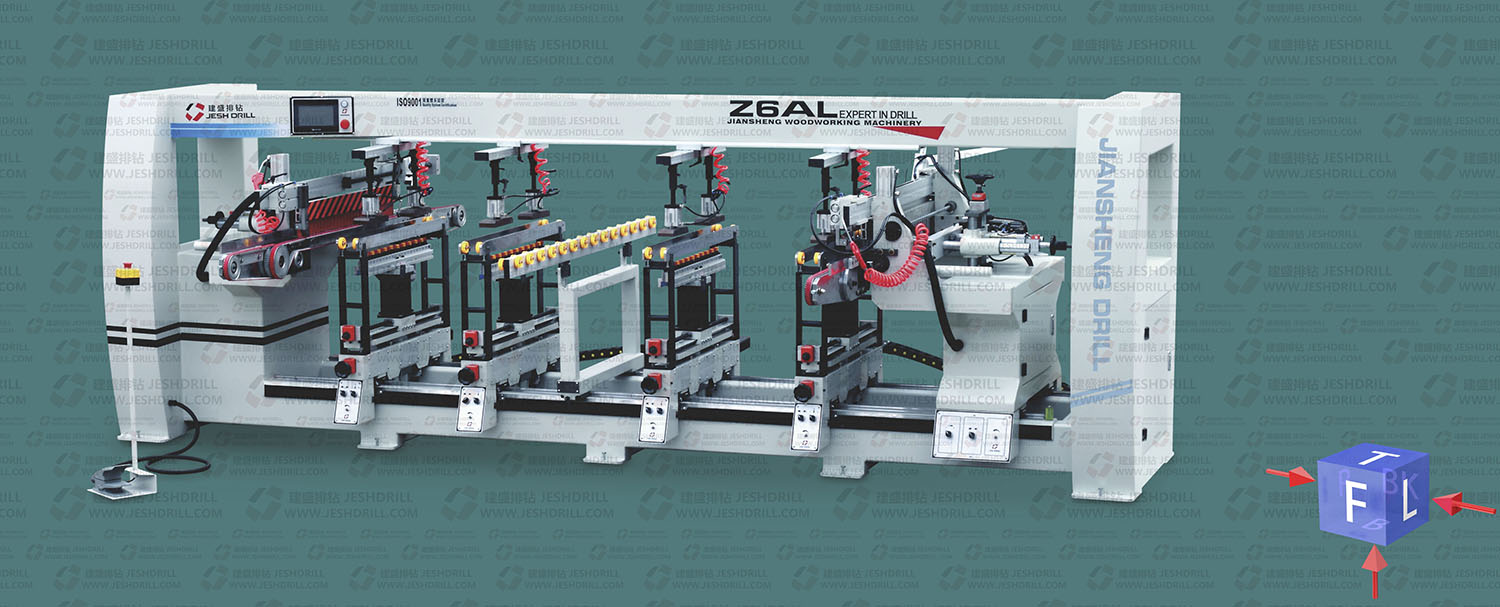

Woodworking six lines auto feeding boring machine

Max. Center Distance Between Holes: L×B = 2450mm × 672mm

Min. Center Distance Between Holes: L×B = 250mm × 32mm

Max. Processing Length: 2450mm

Min. Processing Length: 250mm

Plate Thickness: 8–50mm

Total Number Of Spindles: 126 pcs

Max. Drilling Dia.: 35mm (single bit), 13mm (multi bits)

Max. Drilling Depth: 50mm

Installation Dia. Of Drill Bit Shaft: 10mm

Knife Installation Length: 57mm / 70mm

Spindle Speed: 2840rpm

Qty. Of Horizontal Left & Right Drilling Rows: 2 rows

Air Pressure: 0.5–0.6 mpa

Motor Voltage: 380V, 50Hz

Total Power: 10.1 kw

Net Weight: about 2200kg

Overall Dimensions: 4700 × 2250 × 1650mm

Qty. Of Vertical Up Drilling Rows: 4 rows

Processing Speed: 13–16 pcs/min

Feeding Mode: Auto Feeding

Drill group adopts double linear guide rail which ensured stability and duration.

Famous brand touch screen and PLC control system are applied which makes machine full of power and has low failure rate.

Drill hole range is big,all drill bit using fast connection design ,quick and easy.

The depth and distance of the drill hole will be displayed on the high-precision digital tube which makes the size location fast and precise

High-speed automatic feeding device run smoothly,processing efficiency is 15-20 times per minute

Machine use frame structure ,solid body ,and set with emergency stop devices ,safe and reliable.